The Kerala government recently announced the State’s first waste-to-energy project in Kozhikode.

Key Points On Waste-to-Energy Project?

- The planned facility is expected to be built in two years and generate about 6 MW of power.

- There are around 100 waste-to-energy projects around the country but only a handful of them are operational, due to various production and operation challenges.

- Waste-processing infrastructure is a good way to deal with the mountains of waste that Indian cities produce

Background Of Waste-to-Energy Project

- Solid waste in India is 55-60% biodegradable organic waste

- This can be converted into organic compost or biogas; 25-30% non-biodegradable dry waste; and around 15% silt, stones, and drain waste.

- Of the non-biodegradable dry waste, only 2-3% – including hard plastics, metals, and e-waste – is recyclable.

- The remainder consists of low-grade plastic, rags, and cloth that can’t be recycled.

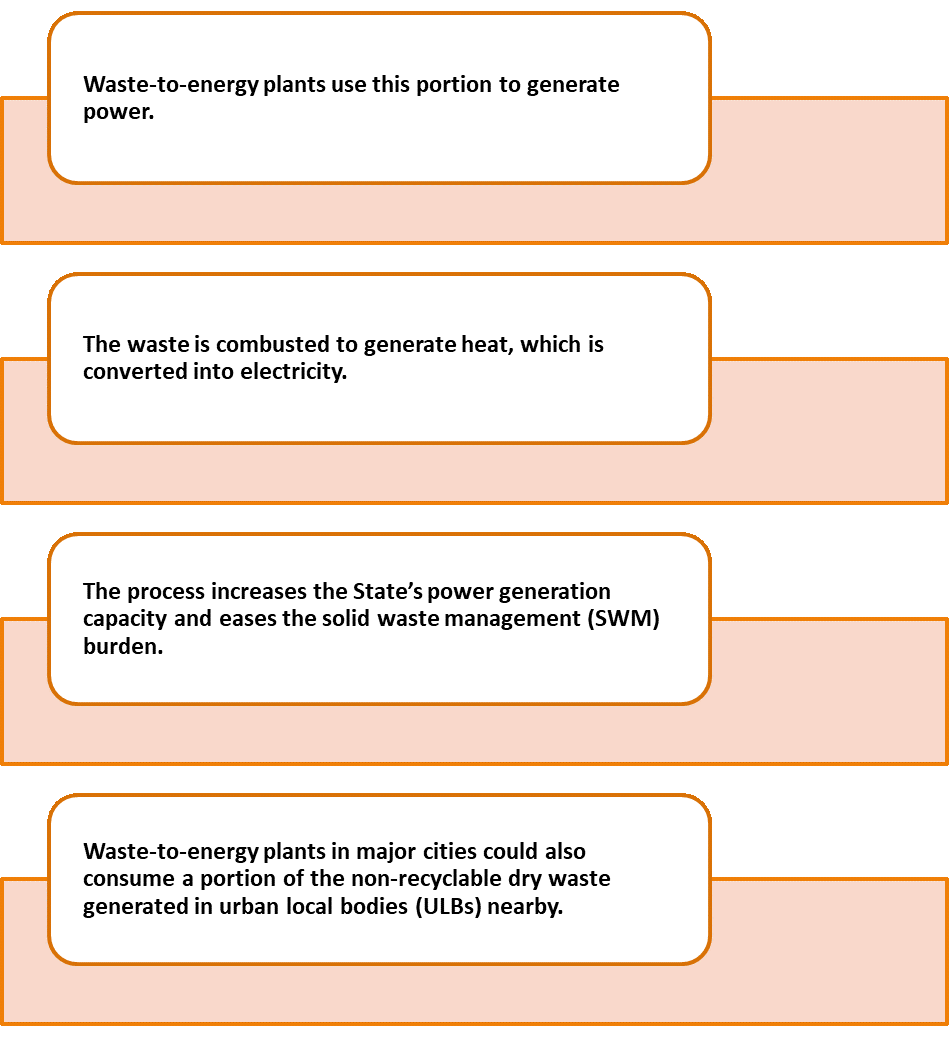

- This fraction of the non-recyclable dry waste is the most challenging portion of the present SWM system; the presence of these materials also reduces the efficiency of recycling other dry and wet waste.

What Do Waste-To-Energy Projects Do?

Need Of waste-to-energy Project

- Kozhikode has a population of about 6.3 lakh and generates approximately 300 TPD of waste. Of this, around 205 TPD is biodegradable and 95 TPD is non-biodegradable.

- The municipality is currently managing the biodegradable material to generate organic compost in various composting plants.

- The centralised composting plant at Njeliyamparamba processes about 100 tonnes of biodegradable waste to generate organic compost.

- Of the non-biodegradable waste, only about 5 TPD out of the 95 TPD is recycled; the remaining non-recyclable dry waste could be used to generate power at the waste-to-energy plant.

Waste-to-Energy (WTE) Technologies

- Biomethanation: It is an anaerobic digestion of organic materials which converts them into biogas. Anaerobic digestion is a bacterial fermentation process that operates without free oxygen and results in biogas containing mostly methane (~60%), carbon dioxide (~40%) and other gasses. Biomethanation has dual benefits. It gives biogas as well as manure as the end product.

- Incineration: It is the complete combustion of waste with the recovery of heat to produce steam which in turn produces power through steam turbines.

- Gasification: It is a process which uses high temperatures (500-1800 degrees C) in the presence of limited amounts of oxygen to decompose materials to produce synthetic gas (a mixture of carbon monoxide (CO) and hydrogen (H2)). Biomass, agro-residues, segregated MSW and RDF pellets are used in the gasifier to produce Syngas. This gas further can be used for thermal or power generation purposes.

- Pyrolysis: Pyrolysis uses heat energy to break down combustible materials in the absence of oxygen. It produces a mixture of combustible gasses (e.g. methane, complex hydrocarbons, hydrogen, and carbon monoxide), liquids and solid residues.

Why Do Waste-To-Energy Plants Often Fail?

- First is the low calorific value of solid waste in India due to improper segregation.

- Calorific value refers to the amount of heat energy released during the complete combustion of a unit mass of fuel.

- Second is the high costs of energy production.

- Third, Many waste-to-energy projects have failed because of improper assessments, high expectations, improper characterisation studies, and other on-ground conditions

To Download Monthly Current Affairs PDF Click here

Click here to get a free demo

Everything About CLAT 2025

Frequently Asked Questions

Waste-to-energy plants uses the waste is combusted to generate heat, which is converted into?

Waste-to-energy plants uses the waste is combusted to generate heat, which is converted into Electricity

Incineration Waste-to-Energy (WTE) Technologies is the complete combustion of waste with the recovery of heat to produce steam

The Kerala government recently announced the State’s first waste-to-energy project in?

The Kerala government recently announced the State’s first waste-to-energy project in Kozhikode